Intelligent PCB Transport for X-ray Inspection System

Reduced handling time with intelliFLOW

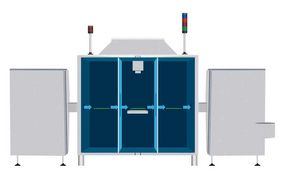

The automatic X-ray system X Line - 3D from GOEPEL electronic has a new, intelligent PCB transport to reduce the PCB handling time. This also results in a shorter overall cycle time and thus a higher throughput.

Electronic assemblies can be very different in their characteristics. Differences include size, weight and friction coefficient. The intelligent PCB transport intelliFLOW automatically determines the optimum transport parameters taking these values into account. As a result, users get a product-specific optimised handling time and reduced overall cycle time. The transport speed is adapted fully automatically to the assembly in order to always guarantee the shortest handling time. Furthermore, the AXI system consists of three independent conveyor modules inside. These enable parallel loading, inspection and unloading. Thus, the PCB under inspection is released immediately after image acquisition and transported to another belt module for post-processing (image processing, data export, MES, ...). A lock system built into the system prevents X-rays from escaping during the module change.

The new intelliFLOW feature is available from version 4.3 of the PILOT Inspect machine software.

Contact

Contact