THT Line · 3D

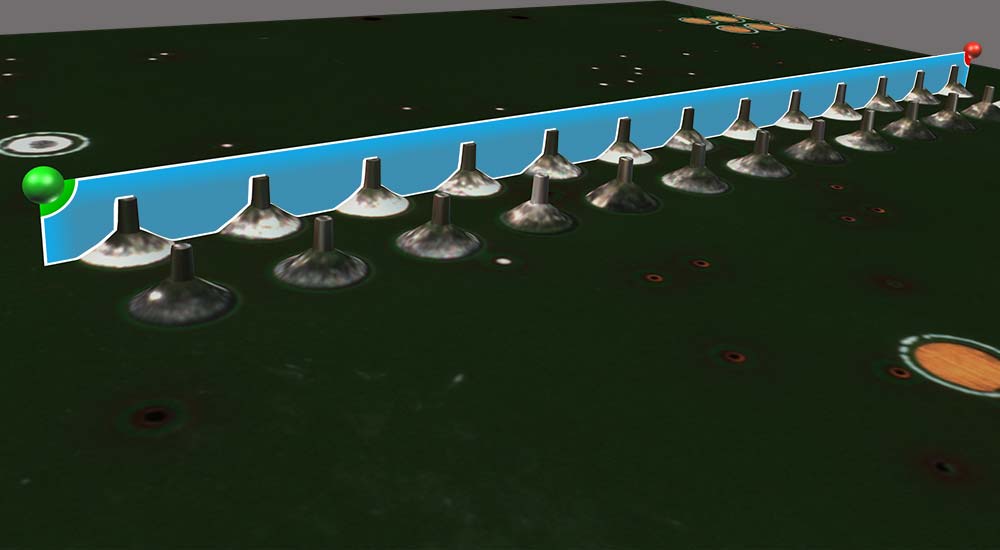

The THT Line - 3D is an AOI system for the inspection of THT components, THT solder joints and wave soldered SMD components in a single system. With up to 8 angled view cameras, concealed components and lateral markings can also be inspected. The inline system inspects THT and SMD components from the top. A new 3D camera module below the conveyor belt simultaneously and independently performs a 3D inspection of the THT solder joints and pins. This allows solder volume, solder flow and pin height to be precisely measured and defects reliably detected.

The automatic or manual feeding of assemblies can be performed out with or without workpiece carriers. Thanks to a height-adjustable camera module, the THT Line · 3D allows a component clearance of up to 140 mm.

Highlights

- unique multispectral illumination

- 4 or 8 angled-view cameras

- THT component, THT solder joint and wave-soldered SMD component inspection

- freely configurable test functions and illumination opportunities

Software

- outstanding ease of use with the system software PILOT AOI

- highest fault detection through different inspection methods as well as individually expandable inspection functions and library entries

- maximum inspection reliability through verification of the inspection depth and monitoring of defect detection

Speed Advantages over common AOI Systems

- ”flip free“ double-sided inspection of THT assemblies

- multiple and independently working AOI modules in one system

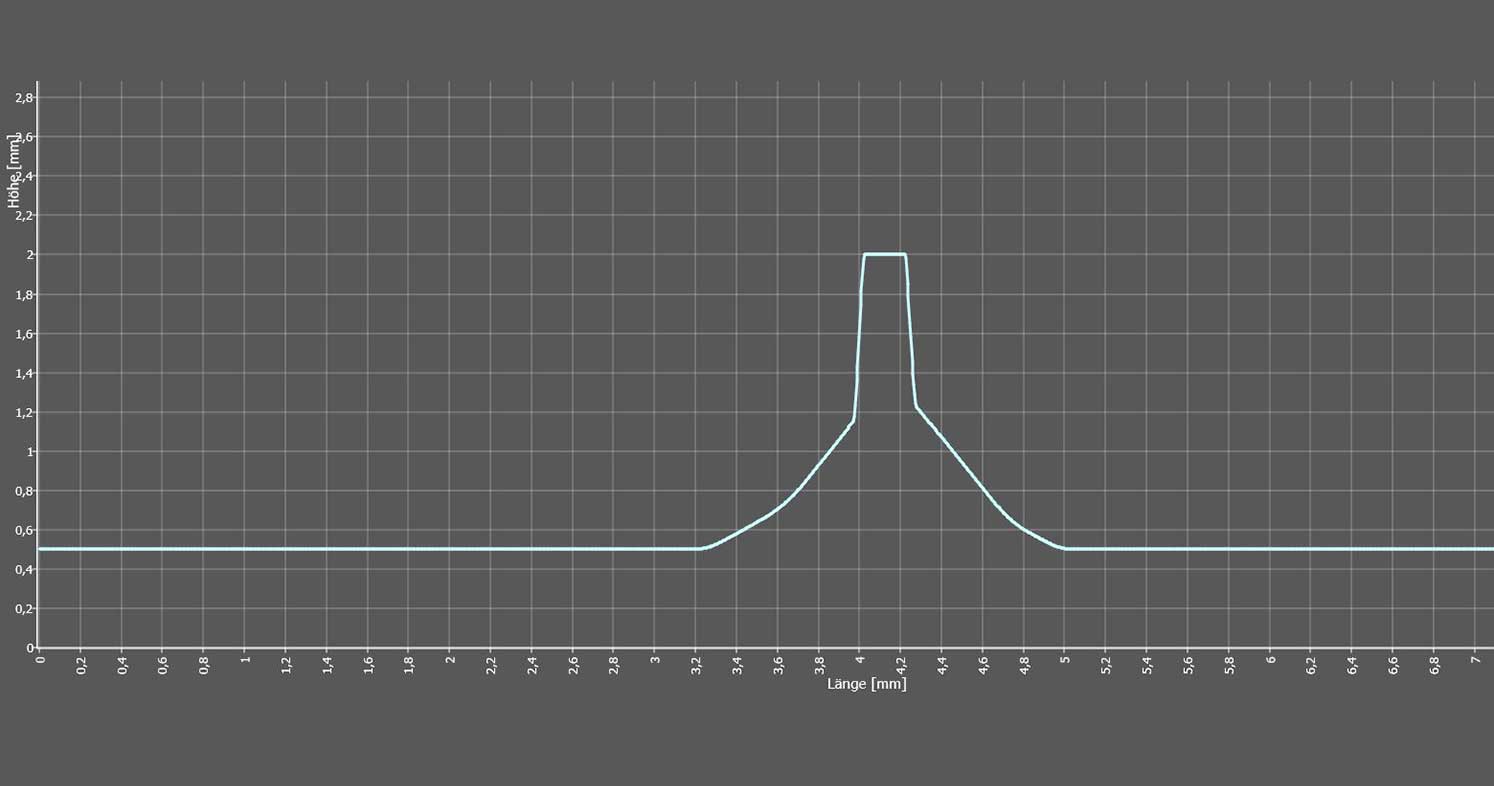

3D inspection of THT solder joints

- determination of solder flow, solder volume and pin height of THT solder joints

- inspection of the PCBA bottom side, both from above and below

- cost-effectife system configuration

- can be integrated into AOI system THT Line, optionally with workpiece carrier return in the lower section of the AOI system

- inspection of THT assemblies with or without workpiece carriers

Integration Options for THT Production Process

- manual or automated feeding

- component side and solder side can be inspected at multiple positions within the production line

- solder side inspection either on the upper conveyer belt or during the PCB return in the lower system area

- generates production-ready test program including component library in only a few minutes

- PCB-specific layout is considered through import and automatic analysis of Gerber data

- optimization of inspection parameters based on sample PCB and IPC standard

- efficient use of AOI already for second PCB

- up to 80% time savings for test program generation and optimization

- guarantees return on investment in the shortest time

Contact

Contact