Automatic Solder Bead Detection Prevents Sudden Circuit Shorts

New test function automatically examines the entire assembly for solder beads

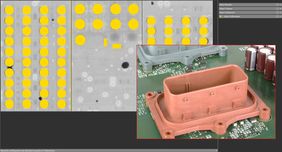

The automatic X-ray system X Line·3D from GOEPEL electronic now has a new test function for automated detection of solder beads. Solder residue of this type frequently occurs in the production process and has various causes. Since they can cause short circuits, they represent a significant danger for safety critical applications, e.g. in the automotive industry.

The new test function of the system software PILOT AXI offers fully automated examination of the entire assembly for solder beads. The detection is independent of flux residue, solder resist and general impurities. Due to its higher density, the solder is more contrast-rich in the X-ray image and can be detected with the least pseudo-error rate. As opposed to a pure optical inspection, the X-ray technology is independent of reflections or shadows on the assembly. In the same way, solder residue situated under component housings can be found.

Solder beads occur due to various causes during wave, selective and reflow soldering. The risk is particularly high for large-area solder joints, e.g. for QFN heat sinks or pin-in-paste connectors.

Demande

Demande