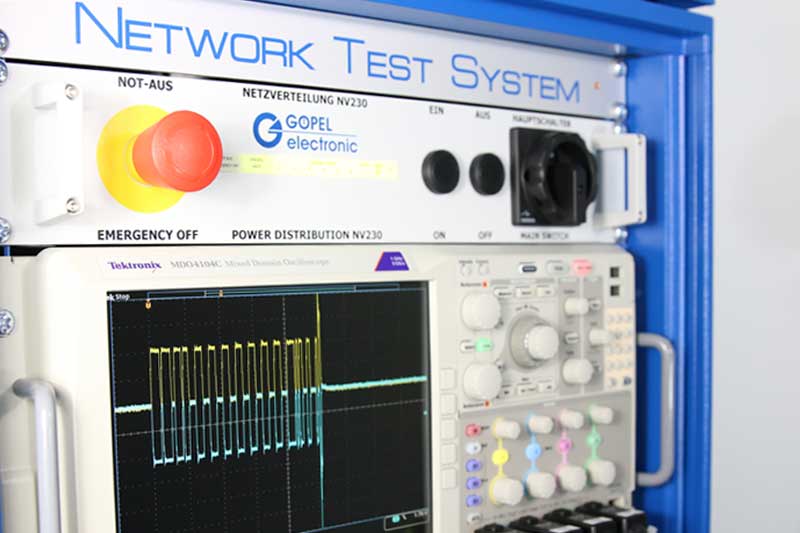

A network testing system allows statements on the physical properties of bus interfaces, the checking of communication properties as well as the simulation of transfer fields on the individual control device, even in a group.

With the combination of measurement technology and diagnosis functions within the network system, this allows special network tests to be realised, the carrying out of which was previously often costly and not automated.

The network test determines whether a control unit can send and receive data to the right specification under all possible operating conditions in the motor vehicle. Whether a control unit affects communication within the vehicle environment or in the case of disrupted communication carries out unchecked reactions can be checked with the network testing system.

Testing and validation of automotive ECUs in development

MagicCAR compact

MagicCAR compact is a compact desktop testing environment for in-vehicle network testing and functional testing in one device. The system has a programmable power supply with switchable terminal signals and integrated current measurement. MagicCAR Compact Net is your solution for automotive networking tests and many other applications.

Determination of the sampling time for CAN/CAN-FD

Sample Point System

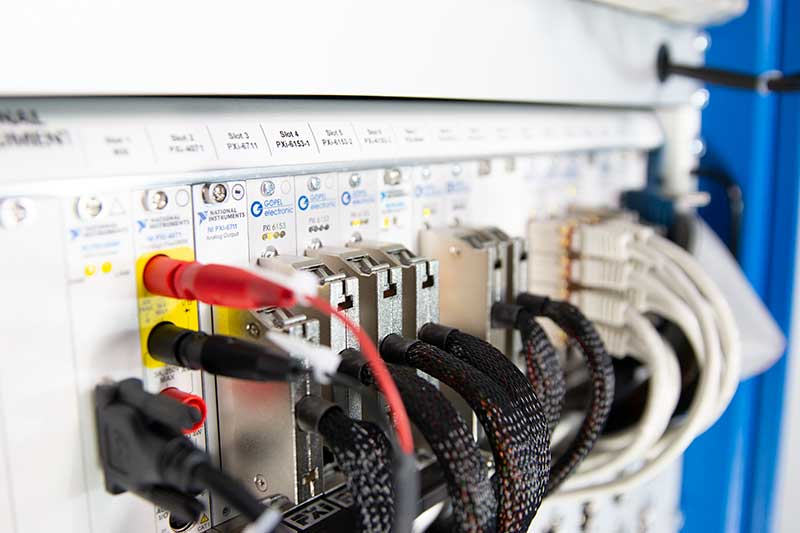

The Sample Point System is a system to determine the sampling time for CAN/CAN-FD. The box is an optional add-on for the standard network test system by GOEPEL electronic. The Sample Point System allows determination of the sampling time with modified CAN/CAN-FD frames even in case of collisions (simultaneous bus access) and thus under real conditions. The collisions are reliably detected and specially handled. The measurement is repeated with the current parameters.

Highlights

- Patented collision tolerant method

- Measurement of the sample point for CAN/CAN-FD (arbitration and data phase)

- +/- 1 % accuracy of measurement

Connection to the network test system is realized via the Ethernet host interface.

The test sequencer software from GOEPEL electronic ensures easy integration of the measurement.

Service

GOEPEL electronic supports you with the development-related qualification of ECUs and their tests. The concrete error analyzes can be integrated directly into your developments and thus secure your own projects. Through the creation of automated and reproducible test sequences, progress is documented.

CAN / CAN-FD

- Cross section requirement specification HS_CAN_LAH_V57F

- VW 80110, VW 80111, VW 80118, VW 80000

- VW End-to-End Communication Security

- DT Network Management Specification

- JLR Design Verification Method for CAN Network Management

- FIAT Off-vehicle physical level test 7-Z0145

- BMW, FORD Conformance

- Other

Demande

Demande