固体振动噪音分析

为了准确评估车身中有旋转或平移功能的机电驱动零部件的质量,噪声分析变得越来越不可或缺。除为降低噪音外,CARoLINE识别不同的噪音还有助于来评估制造工艺质量。

CARoLINE系统包括:固体振动加速度传感器、数据采集模块和系统分析软件。传感器通过磁铁被固定于产线的金属支架上或与DUT连接接触。GOEPEL将与您一起选配适合的传感器型号,为您提供咨询服务,完成设备到检测系统的集成整合。

软件

该软件采用模块化设计结构,支持并行执行所有分析程序。

单个计算评估的触发条件和参数化可通过数据服务器中的入站数据流进行并行处理,由此客户可以设置多个处理步骤多模块并行运行,并参数化测试步骤。

编辑器可用于编辑测试程序。

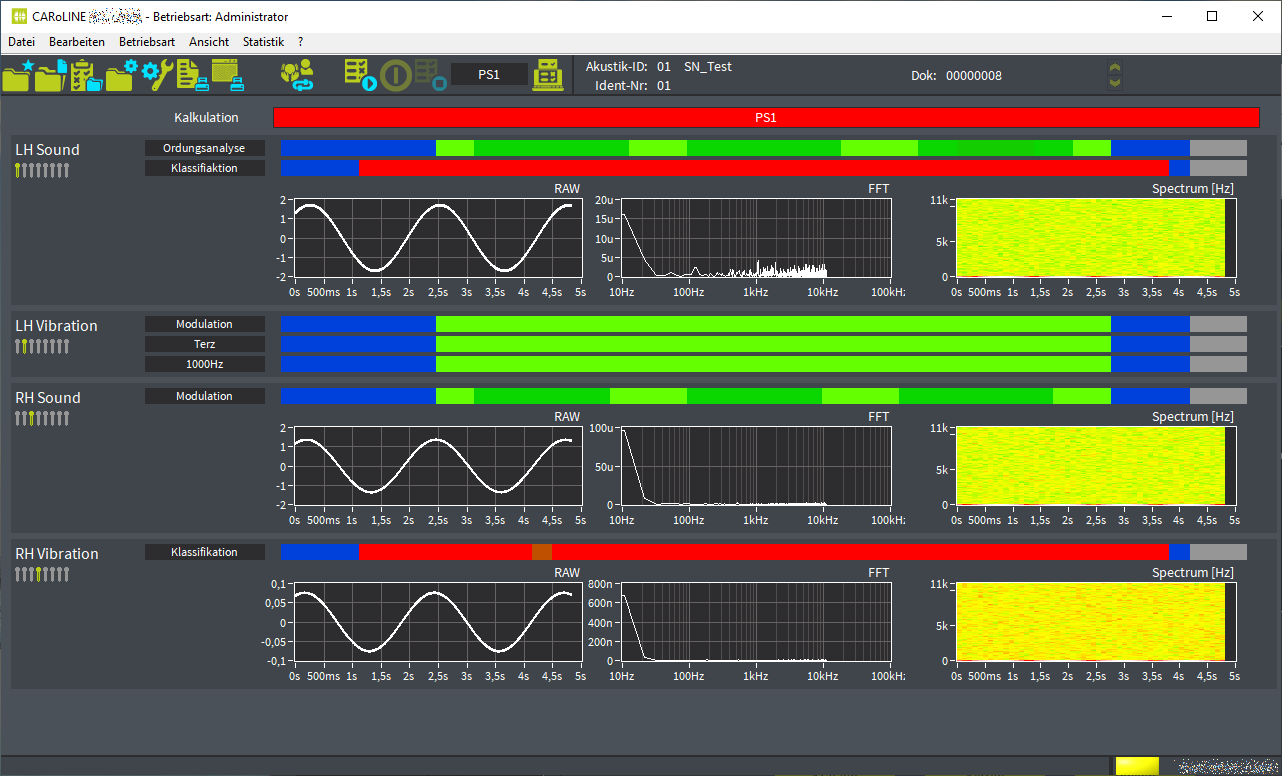

Anzeige von Rohdaten, FFT und Spektrum des Sensors pro Kanal.

Anzeige von Rohdaten, FFT und Spektrum des Sensors pro Kanal.- Status der Prüfschritte:

blau = CutOn- und CutOff-Grenzen | grau = unbenutzt | gelb = in Arbeit | grün = Ergebnis ok | rot = Ergebnis nicht in Ordnung

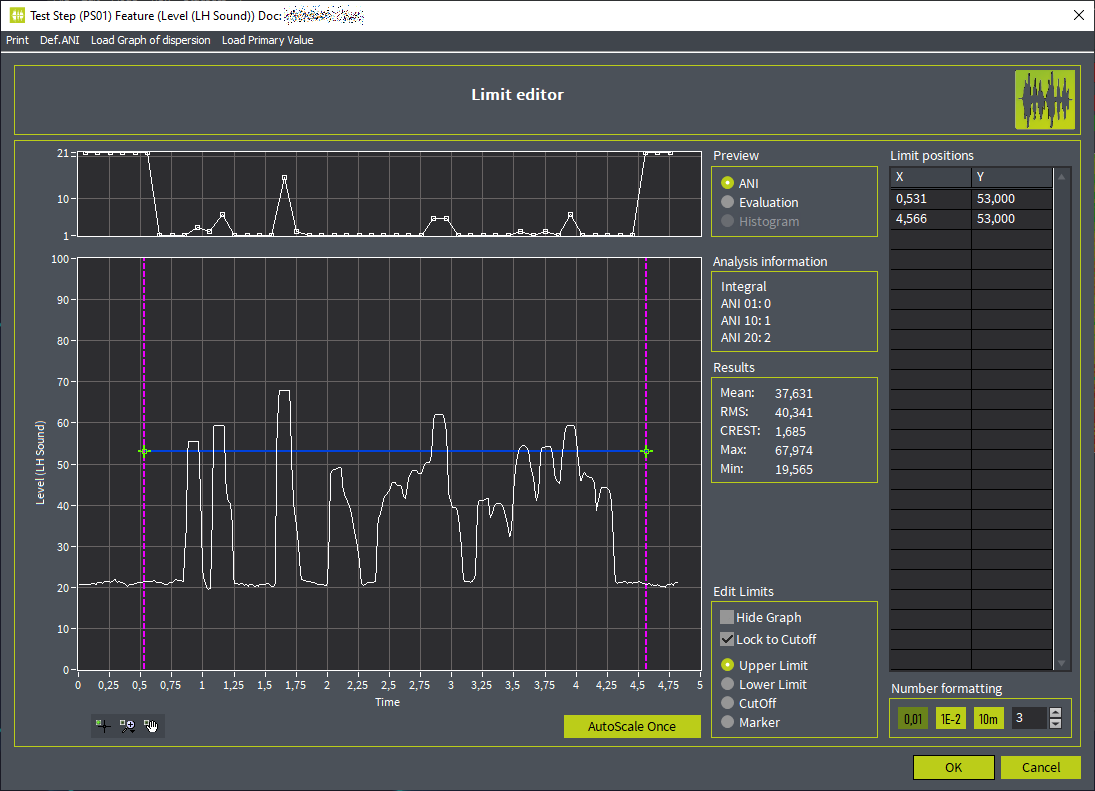

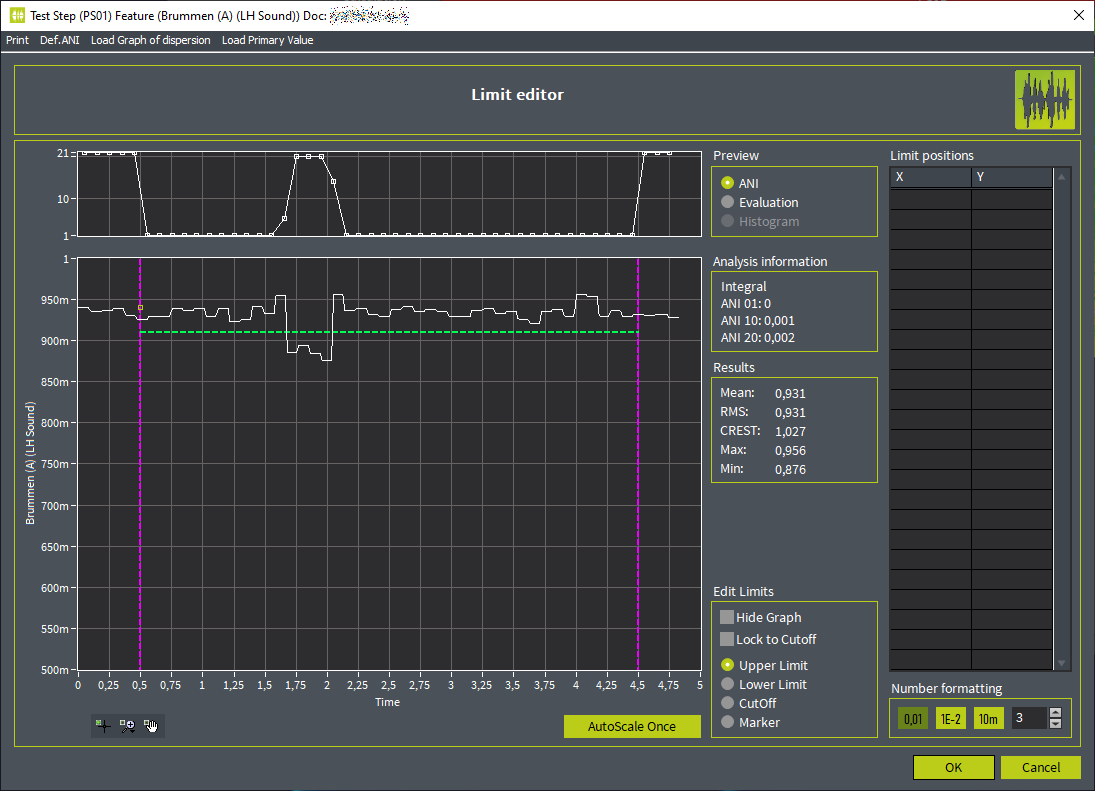

Bewertung eines zeitlichen Signals nach der Analyse

Bewertung eines zeitlichen Signals nach der Analyse - Definition von CutOn- und CutOff-Grenzen für zeitliche Eingrenzung sowie Pegelgrenzen für Eingangsdaten

- Erstellung eines Diagramms mit Häufigkeitsverteilung möglich, um Trends in Aufnahmen zu erkennen

Bewertung eines Signals nach der Analyse durch ein neuronales Netz

Bewertung eines Signals nach der Analyse durch ein neuronales Netz- Definition von CutOn- und CutOff-Grenzen für zeitliche Eingrenzung der Bewertung

- Definition von Grenzen für Wahrscheinlichkeitswerte

- Erstellung eines Diagramms mit Häufigkeitsverteilung möglich, um Trends in Aufnahmen zu erkennen

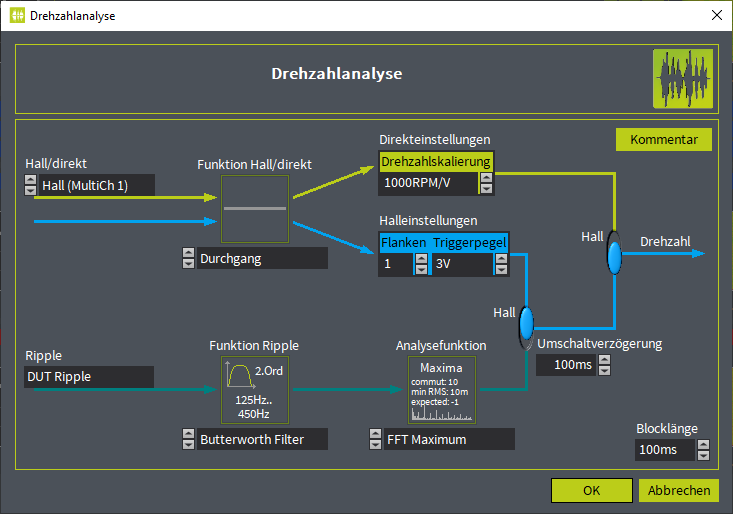

Drehzahlanalyse

Drehzahlanalyse - Definiton der Berechnung der Drehzahl

- Grundlage sind Stromripple-Signal, das Hall-Signal oder ein direktes analoges Signal

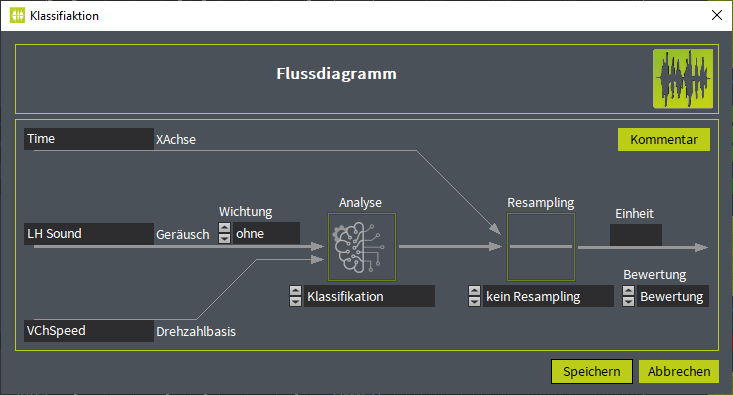

Definition der Berechnung eines jeden Merkmals im Flussdiagramm

Definition der Berechnung eines jeden Merkmals im Flussdiagrammlinks im Bild: Eingangskanal (Messsignal) mit aufgenommenen Geräusch

- Für eine Pegelanalyse eines Mikrofonsignals empfiehlt sich eine "A"-Wichtung.

- es folgt die Signalanalyse (im Beispiel die Klassifikation), die hier ausgewählt und parametriert werden kann.

- optionales Resampling, dabei wird die…

Artificial Intelligence

CARoLINE can be equipped with optional AI connection interfaces.

→ Read more about AI for Sound Analysis

Modulation analysis of exterior mirrors

The so-called modulation analysis is intended to find out how strongly a certain frequency fluctuates in the course of a selected movement - for example, during the unfolding movement of the vehicle exterior mirror. If this fluctuation around the determined centre frequency is too strong, this can be perceived as an unpleasant lyre.

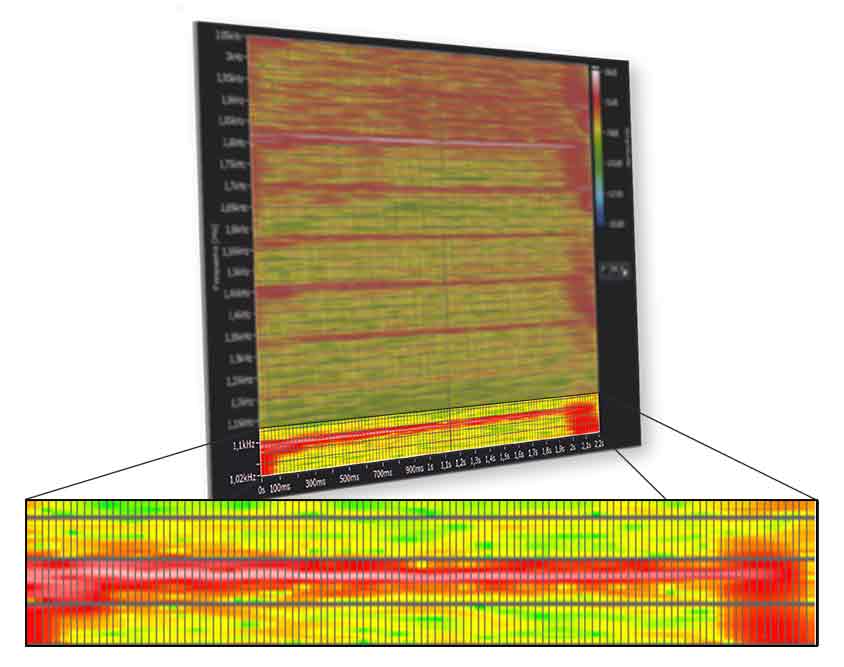

The results of a modulation analysis can look like this, for example:

fcenter = 1087 Hz , f fluc,p = 43 Hz

f fluc = 19 Hz ⇒ Modulation test OK

The centre frequency fcenter sets the value for the permitted frequency fluctuations f fluc,p, f fluc for the fluctuation that actually occurred. The fluctuations that occurred with this exterior mirror are within the permitted limit.

Modulation tests can also be determined for frequencies that continuously shift towards higher or lower frequencies over the test time. It does not matter whether this is a linear process or not. Only the calculation method differs here.

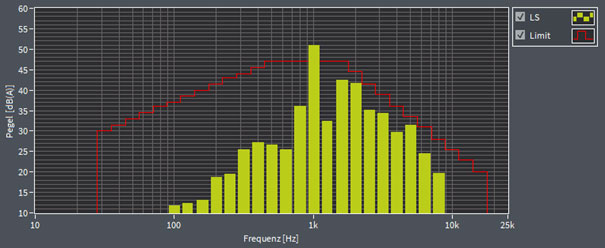

Third-octave analysis on side mirrors

With the so-called third-octave analysis, conspicuous frequency ranges can be determined very quickly and monitored using limits. In addition, the third-octave analysis serves as a basis for determining the tonality of the mirror, which can be used to test whether it causes a melodious or disturbing noise.

In this third-octave analysis, the third octave of the frequency 1000 Hz exceeds the set limit and thus also the set tolerance limits.

These acoustic analysis procedures are used for quality assurance of complex assemblies that become conspicuous in the end-of-line test. Assembly errors or susceptible drive systems can be quickly localised.

联系我们

联系我们