Inspection of SMD assemblies with Vario Line · 3D

AOI all-rounder Vario Line · 3D for the highest quality standards.

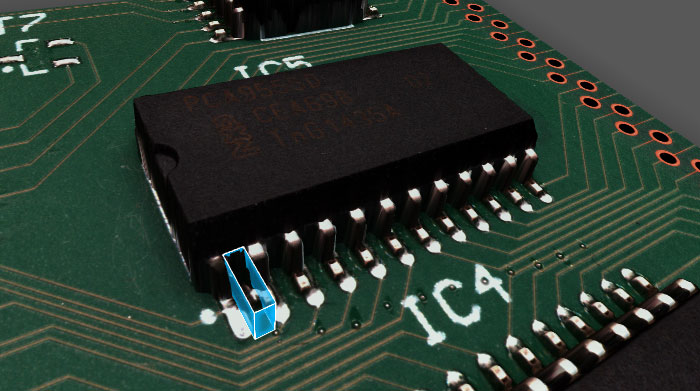

Vario Line combines the best in fault detection, customer specificity and economic viability using 3D measurement technology and 2D image capturing. Four angled-view cameras and the additional rotary drive allow shadow-free inspection and measurement from 360 degrees. A new axis system based on linear actuators has also been integrated, which impress with outstanding dynamic features and highest positioning speeds. Due to the high optical quality, false calls are significantly reduced. At the same time, cycle times are kept low for efficient use.

The new 3D AOI generation

- new 3D camera module for increased fault detection and reduced false calls

- highest optical quality for projection and image acquisition

- dynamic adjustment of inspection parameters

- measurement of components up to 35 mm

- inspection of optically critical surfaces with large dynamic range

- optionally available: 3-segment belt module for assembly transport

- during the inspection process the next assembly is loaded

- at the same time, the inspected assembly is handed over to the next module

- handling time is reduced by several seconds

Highlights

- maximum fault detection

- variable 360° inspection in 1° steps at constant resolution and definition

- unique multispectral and multidimensional illumination

- combined 2D/3D technologies

- customer-specific inline integration with flexible interfaces (Hermes, Pulse etc.)

- Longboard-AOI or AOI for inspection of continuous material

- Integration of additional test procedures (e.g. electrical tests) in the AOI system

- very high component clearance (e.g. for THT components)

- Inspection of assemblies with and without workpiece carriers

- double-sided THT inspection in one system

- Initial sample inspection

- Import and classification of defect data, also from external systems

- Individual MES connection on delivery

- 3D AOI system with manual loading

Software

- outstanding ease of use with the system software PILOT AOI

- highest fault detection through different inspection methods as well as individually expandable inspection functions and library entries

- maximum inspection reliability through verification of the inspection depth and monitoring of defect detection

"AME" Applied Micro Electronics

AME located in Eindhoven, Netherlands are using 9 systems from GÖPEL electronic for their SMD and THT production.

- generates production-ready test program including component library in only a few minutes

- PCB-specific layout is considered through import and automatic analysis of Gerber data

- optimization of inspection parameters based on sample PCB and IPC standard

- efficient use of AOI already for second PCB

- up to 80% time savings for test program generation and optimization

- guarantees return on investment in the shortest time

联系我们

联系我们