X Line · 3D

Le système X Line · 3D est un système AXI en ligne pour une inspection 3D haut de gamme, destiné à la production de masse. Il est utilisé pour assurer la qualité de cartes électroniques complexes grâce à une grande rapidité d'inspection.

L'inspection rayons X tridimensionnelle capture la face soudure et la face composants lors d'un même processus. En combinant l'inspection rayons X avec un module AOI, des opérations d'inspection peuvent être également réalisées ce qui serait impossible en utilisant l'inspection rayons X seule (AXI).

Applications

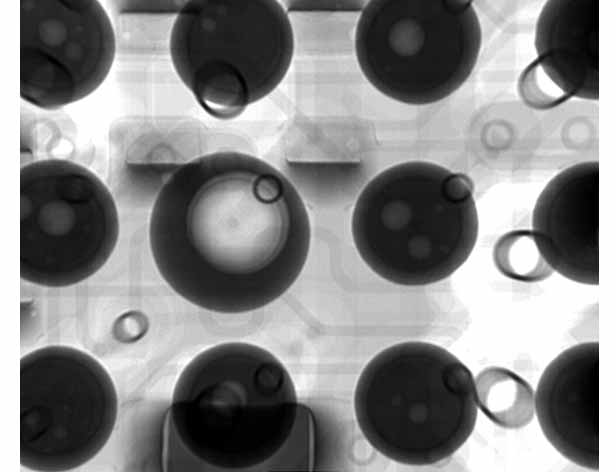

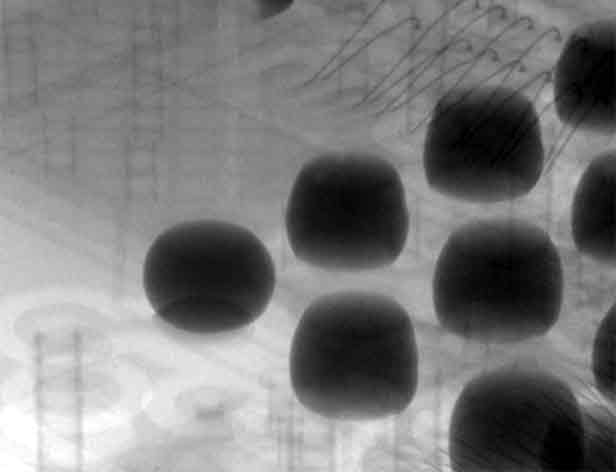

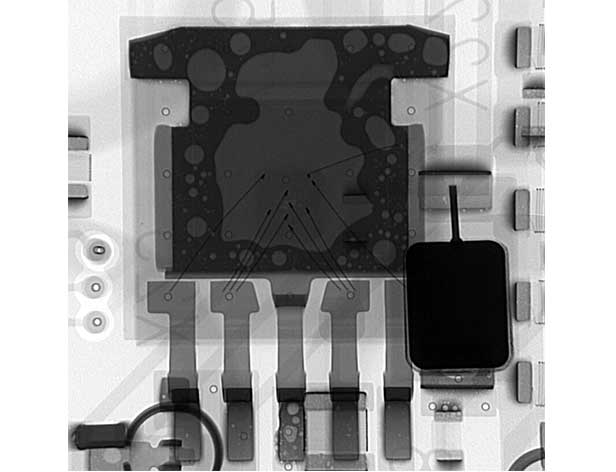

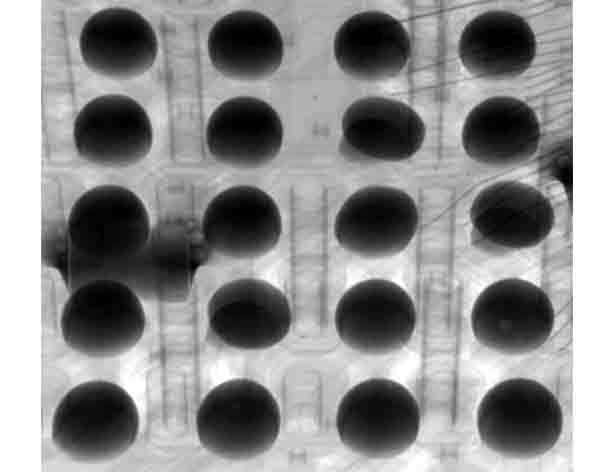

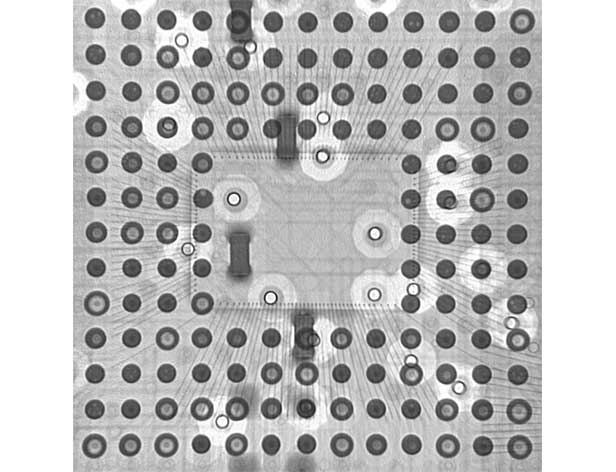

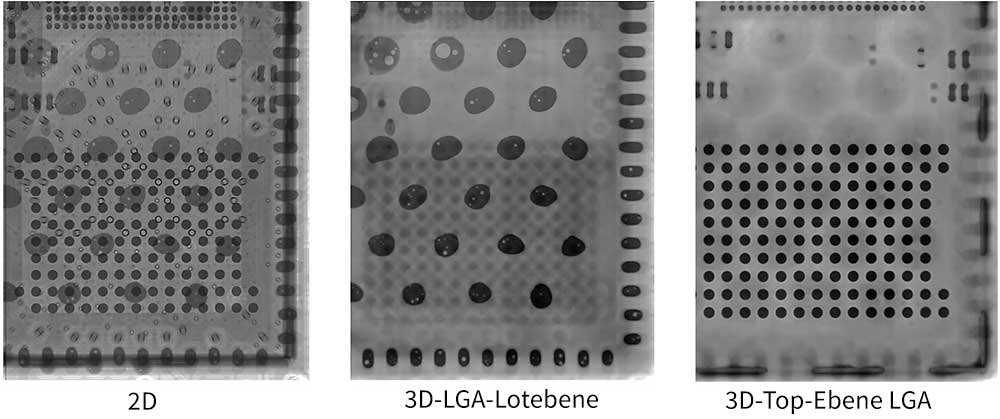

The AXI systems from GÖPEL electronic are versatile. Standard tasks include the inspection of BGA, QFN, THT, LED and LGA solder joints. In addition, all other solder joints, whether visible or hidden, on a PCB can be inspected. Press-fit connectors are also inspected using the 3D planar CT process. During X-ray inspection, there are no AOI-typical reflections and shadows that could influence the inspection. The inspection is based on the absorption of the material which has different densities and thicknesses. The color and gloss level of a surface do not influence the X-ray inspection.

Detector technology

The X Line systems are equipped with multiple digital, bidirectionally scanning line detectors (MultiAngle Detector). The MultiAngle Detector enables simultaneous 2D, 2.5D and 3D image acquisition. Unlike flat-panel detectors, which use stop-and-go motion to acquire images, X-ray images are acquired directly as they move. This results in short image acquisition times and reduces cycle time.

The 2D, 2.5D and 3D image acquisition time can be adjusted by the programmer to match the available cycle time. The number of oblique projections for reconstructing a 3D X-ray image is also freely configurable. In the offline programming software, 2D, 2.5D and 3D technology can be selected depending on the inspection task in order to achieve optimum inspection coverage.

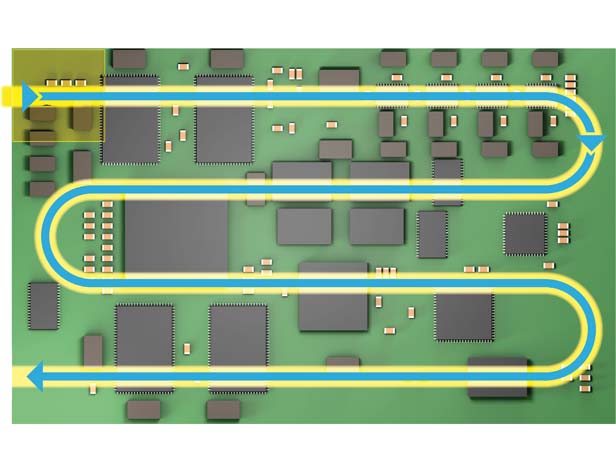

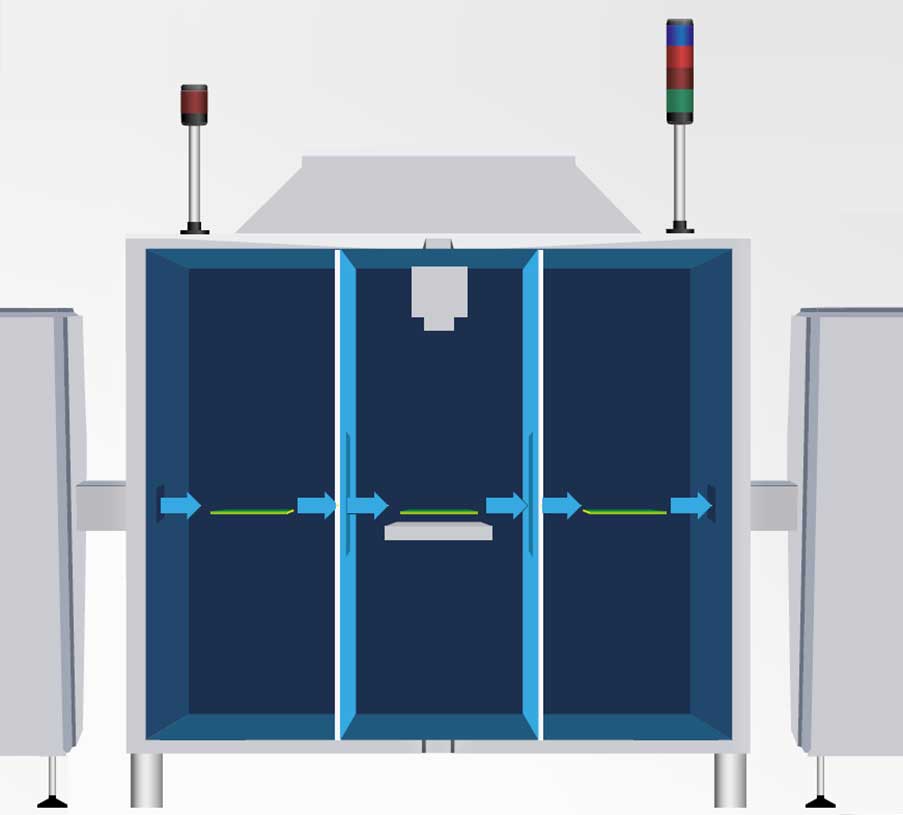

Conveyor transport

Three separate conveyer modules are installed inside the X Line systems. This enables parallel loading, inspection and unloading of PCBs. After the image acquisition is completed, the PCB is transported to the next conveyer module for post-processing. The next PCB to be inspected moves directly to the next module. Post-processing (image processing, data export, MES) is thus parallelised.

Integrated lead bulkheads prevent X-rays from escaping during the PCB change. This design reduces the handling time and thus the total cycle time.

intelliFLOW

Not every PCB is the same. Differences lie in size, weight and friction coefficient, among other things. The intelligent printed circuit board transport intelliFLOW takes this into account and automatically determines the optimal transport parameters. This enables optimised handling times for specific products.

More Info

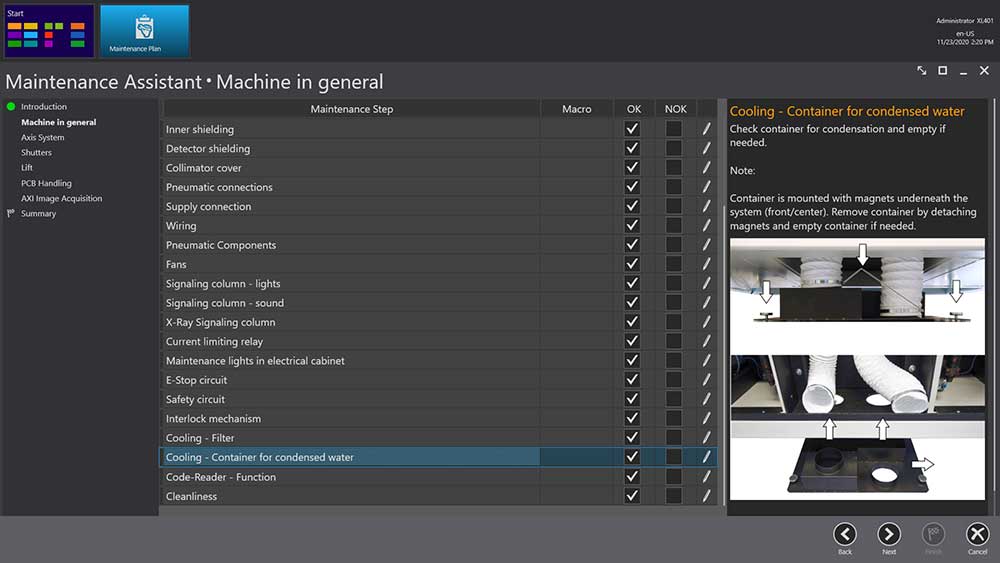

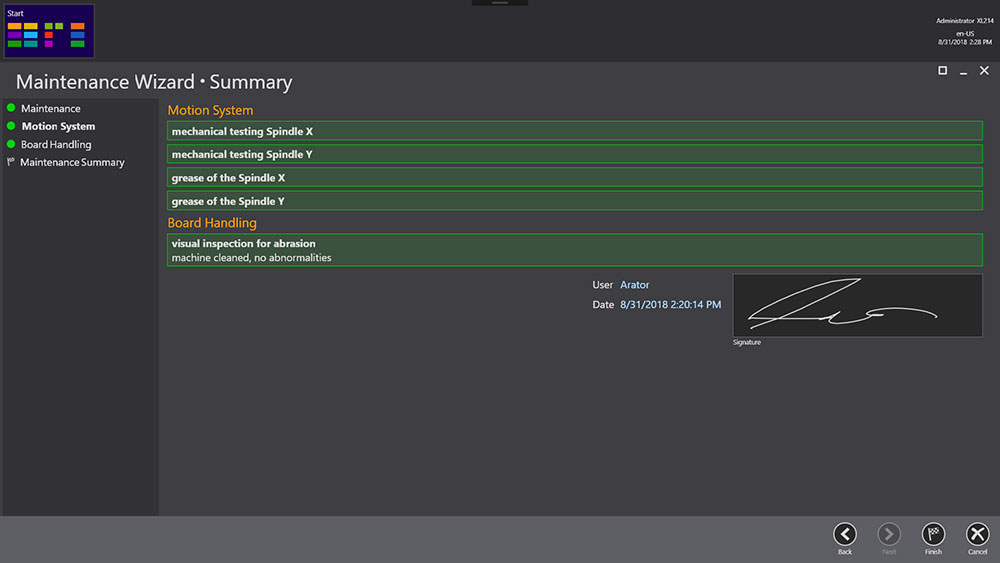

Digital maintenance concept

The AXI systems have a digital maintenance concept. The systems create usage-based maintenance plans and monitor themselves independently.

Each key component of the machine is monitored and a detailed maintenance overview is created. A preventive maintenance plan reduces maintenance and machine downtimes and thus also costs. Usage-related values such as kilometres travelled, pneumatic strokes and X-ray source beam hours are monitored.

If the warning thresholds are exceeded, preventive maintenance can be planned - and downtimes are reduced.

Expanded human-machine communication

The AXI systems have four high-intensity light bars integrated into the exterior design to extend human-machine communication. The light bars are located in the corners of the outer cladding and show the operators various system statuses even at a distance. This helps to react quickly to avoid a line stoppage.

Software

The software package is comprehensive and includes several modules. You control the app-based machine software PILOT Inspect via intuitive touch operation in the familiar style of a smartphone. New operators can be trained shortly.

The offline programming software PILOT AXI enables wizard-supported inspection program creation with integrated CAD data import, design library and a wide range of inspection functions.

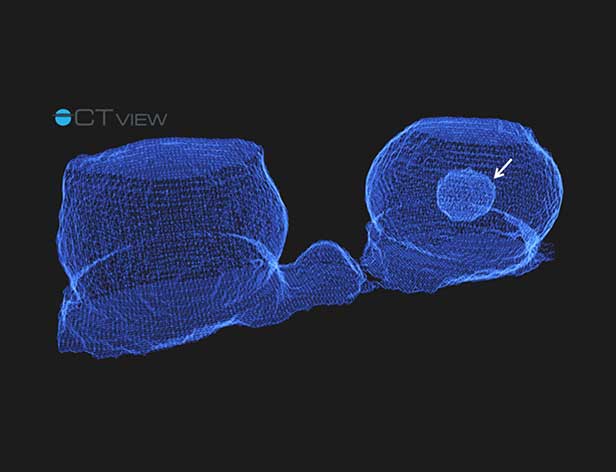

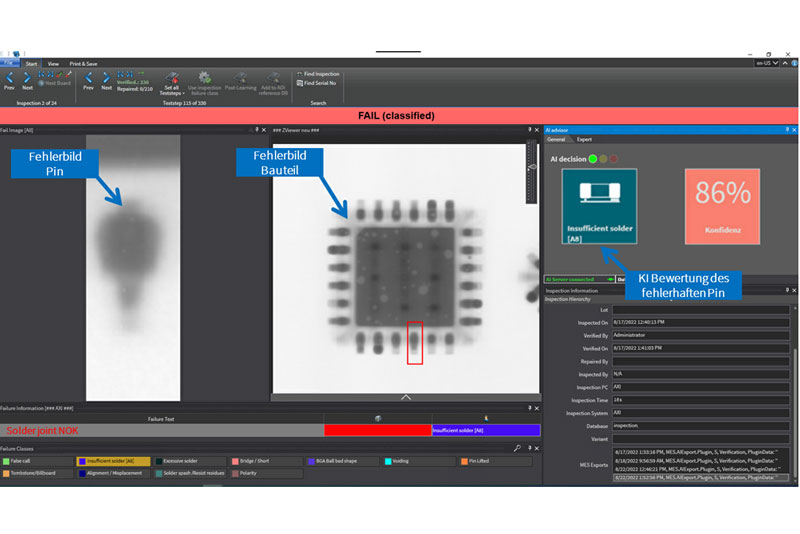

The verification software PILOT Verify for the classification of detected anomalies displays defect images, good comparison images, 2D/ 2.5D and 3D slice images as well as 3D volume reconstructions by means of CTview.

Networking of the AXI system with the outside world is ensured by PILOT Connect via various MES interfaces.

The AI advisor software module ensures defect classification at the verification and repair station

Based on pre-trained models, the AI advisor makes its own decision for each anomaly found by the inspection system. The AI decision is based on the verification decisions made by humans in comparable cases in the past. On the one hand, anomalies that are classified with high confidence as pseudo faults can be evaluated directly by the AI - without human intervention. This saves time.

On the other hand, the AI advisor can warn if a human error would lead to a so-called human escape. If the staff incorrectly classifies a real error as a pseudo error, the user is asked to reconsider his decision. Especially with X-ray images - where interpretation is often more demanding - the AI advisor is a welcome support.

An expert opinion from GÖPEL electronic

The X Line system family offers a complete package for AXI users. In addition to smart hardware features, it is above all the software that makes it possible to effectively create inspection programmes with high inspection coverage.

- Dr. Christian Dreßler – Application Engineer AXI -

Demande

Demande