GÖPEL electronic - Who we are and what we do

Everyone loves it when something runs flawlessly. Particularly for us. Our products and technologies may not be recognisable at first glance in everyday life - yet they are in almost everything. Because: electronics are an indispensable part of our daily lives. And our solutions play an important role in ensuring that things work as they should.

For example, that all functions in the car work correctly and are safe. That our telecommunications run smoothly. That medical technology is reliable and that the smart technologies of everyday life really do help us. Our customers use our solutions to ensure the quality of their premium technology products. With comprehensive test and inspection solutions for electronic assemblies and systems, we achieve the best possible detection of errors in production and development.

So that high-tech works.

We are a family business and our history began in 1991. In the beginning, we tested electronic circuit boards for correct functionality. In the meantime, this has grown into more than 230 GÖPEL employees in four company buildings - with correspondingly numerous new fields of activity.

As co-creators of rapid technological progress, we are constantly experiencing new challenges and our playground is getting bigger every day. We are always looking for creative minds and people with a passion for cutting-edge technology. It is important to us that you feel comfortable. With flexible working options and great colleagues, we ensure a great atmosphere and harmony with personal life.

Would you like to be a part of our Team?

Andreas Türk

Product Manager AXI in the area of inspection solutions AOI/AX/IBV

"I have been working at GÖPEL electronic for about 16 years because here you can constantly develop high-tech products together with a young, committed team. The collegial working environment paired with a flat hierarchy makes it possible to make decisions quickly and unbureaucratically - so your own ideas reach the market faster. For years, there has been a stable economic development at GÖPEL. This makes me and our customers feel well and comfortable."

Automotive Test Solutions

Our test and simulation systems from this area are primarily used in development and production processes in the automotive and supplier industry. Here we deal with modular function test systems and diagnostic tools for control units, or bus communication systems for a wide variety of electronic components in the automobile. Electromechanical assemblies, electric drives and entire seat systems are also tested for correct "end-of-line" functionality with our test systems. In the process, we also rely on artificial intelligence and cobots. In the growth area of e-mobility, we offer test solutions for the electric drive (powertrain) as well as the interior and in-vehicle network.

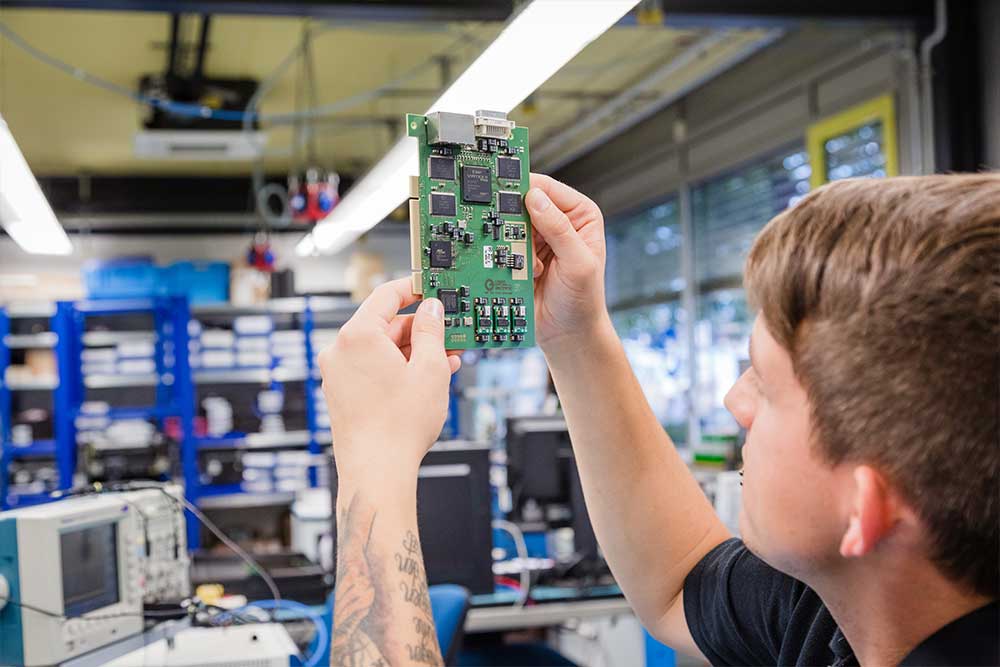

Embedded JTAG Solutions

This business unit deals with the electrical testing and programming of assembled PCBs. This is because today's electronic assemblies are characterised by more and more components in a very small space - in other words, increasing assembly complexity and decreasing access options. This access is needed to contact the electronics during design or manufacturing processes for test purposes. The Embedded JTAG Solutions division explores new ways for reliable, high-performance testing and programming.

Through the multifunctional platform JTAG, we can easily address microprocessors, microchips and other highly complex devices (e.g. FPGA, µBGA or CSP) using integrated boundary scan architectures. We offer a comprehensive range of hardware products and software tools for this purpose.

Inspection Solutions

For electronics manufacturers and EMS service providers (Electronics Manufacturing Services), we offer high-performance and technologically advanced systems for the optical inspection of assembled PCBs. This enables production processes to be optimised and defects in manufacturing to be detected: for example, faulty solder joints, short circuits on high-pole components, incorrectly positioned components or air pockets under BGAs.

The systems can be used at different positions in the manufacturing process, e.g. before and after the soldering process, as inline or stand-alone systems.

Our inspection solutions differ in:

Industrial Function test

Customised test systems for industrial electronics and PLC systems are the subject of the Industrial Functional Test division. Any electronic products can be tested, e.g. programmable logic controllers (PLCs), temperature sensors or heating controls. We develop customised solutions, both for small quantities and for system integration in series production.

Contact

Contact