The years 1990/91 were times of change and new beginnings in Germany, especially in the eastern regions. In this phase, courageous engineers from Jena decided to do what they were refused in the GDR: they founded their own company - today's GÖPEL electronic GmbH. Emerging from the measuring and testing technology department in the Carl Zeiss Jena state combine, we are now considered a leading global manufacturer of test and inspection solutions. The political wind of change at that time and the worldwide pandemic thirty years later mark important milestones - and the story continues. But how exactly did it all begin?

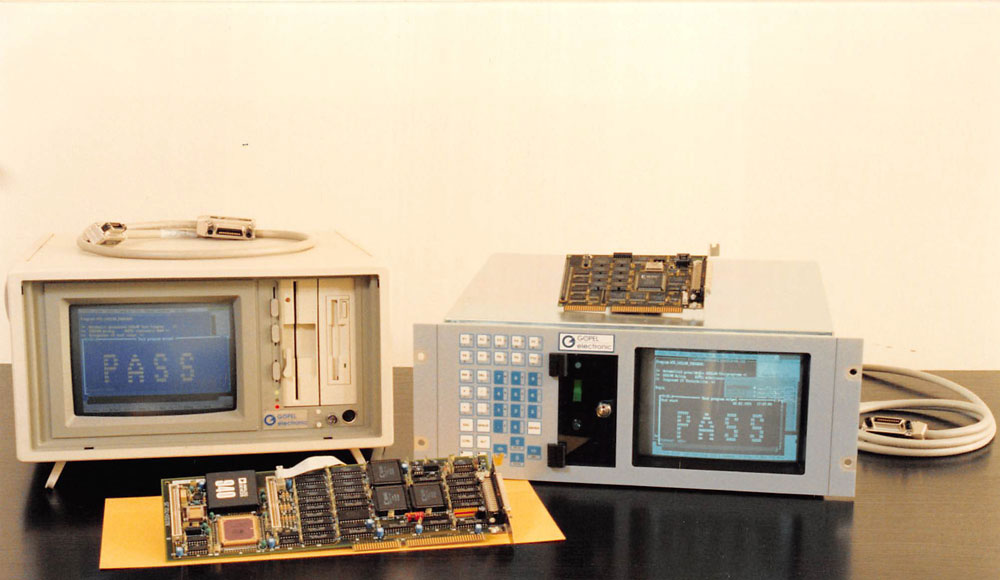

Starting in the premises of the old predecessor company, our founders Holger Göpel, Thomas Wenzel, Manfred Schneider (as well as another fellow campaigner at the time) were able to benefit early on from the many years of experience at Carl Zeiss. The state combine was considered the largest employer in the region, and most people in Jena were also "Zeissians". The department, which was about 50 employees strong, developed computer-controlled testing technology for internal use at Zeiss, e.g. on the basis of function tests and in-circuit tests. In the course of his work, Holger Göpel came across an innovative test procedure called "Boundary Scan", in which he saw a promising alternative in the face of decreasing physical test access to electronic assemblies. History proved him right.

The political and economic transformation of the country opened up the opportunity of independence for the first time, which was pure wishful thinking in the former GDR. On 17 May 1991, GÖPEL electronic GmbH was officially founded, and shortly afterwards the first employees from the former department were hired. This made it possible to bundle know-how and technical expertise with the aim of offering the testing technologies developed in Jena to the world that had just opened up. The discovered boundary scan method was supplemented by "classical" test technology engineering. This included specific test solutions of all kinds, entirely according to the customers' ideas. But as a "start-up" (this term was probably less familiar at that time) with East German roots, it was not easy to gain the trust and eventually orders of customers. When a prospective client asked for references, Holger Göpel answered confidently: "If you have courage, you will be the first reference!". The courage was to pay off for both sides. One by one, more orders followed. The innovative strength was widely known, and GÖPEL electronic gained the trust of the rest of the republic.

The functional testing of electronic assemblies and systems, ...

... especially from the automotive sector, has been a main pillar of our range of services from the very beginning. We soon developed into an established and creative supplier for ECU testing, bus communication and diagnostics. Our solutions quickly met with great interest in aerospace and automation technology as well. In these areas, quality assurance (today more than ever) has a particularly high priority; due to the trust earned, many customers perceived us as a reliable partner. Products such as the "Series 61" interface module or the CARoLINE acoustic analysis system enabled us to make the breakthrough from a project-organised engineering company to a product-oriented developer and manufacturer in the automotive test business field. We also established ourselves in mid-range and luxury cars, for example with the functional test system for vehicle seats "OsCAR", which is used at countless automotive supplier production sites worldwide. All these solutions, which flow together under the umbrella of "Automotive Test Solutions", represent the largest and most successful business area of our company today.

The core of our company ...

... is today's business unit „Embedded JTAG Solutions“. The JTAG/Boundary Scan software environment SYSTEM CASCON, which was already developed in the early years, has been continuously developed and expanded until today - and is now one of the most frequently used platforms of its kind. Innovative technologies, validation strategies, associated hardware components such as SCANFLEX and integrations with many important chip manufacturers in the market soon led us to the top in the field of component testing. Along the way, we formed many well-established partnerships with vendors of other test technologies, which we still maintain today through our ATE integration. But our clever people had even more in mind. With the innovation-driven corporate culture and increasing demand on the market, the expansion of our product portfolio and the associated founding of further business divisions was only the logical consequence.

Continuing a long-standing tradition

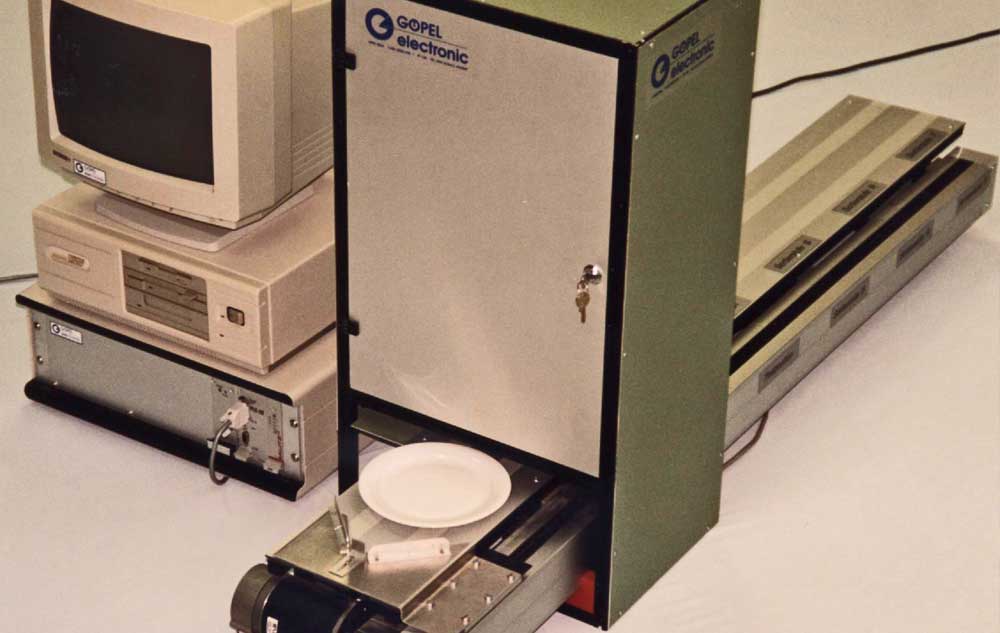

Since not all manufacturing defects are electrically detectable, Automatic Optical Inspection (AOI) was considered in 1992 and a new business division (today "Inspection Solutions") was founded. At the old place of activity of Ernst Abbe and Carl Zeiss, many years of tradition in optics and fine instrument technology could be relied upon.

This resulted in a comprehensive range of customised solutions for the optical inspection of a wide variety of products. The first projects, however, had little to do with electronics; one example was the inspection of porcelain plates for a regional manufacturer. Here, fine ceramic plates were inspected and classified with a system developed by us.

Another notable project was the fully automatic test setup for the series production of counter scales, as found in supermarkets. This test system from 1993 would probably work today under the name "Industry 4.0". Equipped with seven cameras, 11 drive axes and two robots, it was possible to check small quantities efficiently and without expensive manual work steps. The cameras inspected displays and keyboards, a gripper arm performed haptic operations. A barcode scanner recognised product type and automatically assigned inspection sequences from a library. The first fully automatic inspection system from Jena was born. It later brought us to 3D AOI systems, automatic solder paste and X-ray inspection systems as well as AI-based software - albeit no longer for plates and scales, but highly complex and highly miniaturised electronic assemblies.

Soon our products and our reputation went beyond the country's borders. The world was open. And it became an important part of our corporate philosophy to have a global presence. With subsidiaries in the USA, India, China and the United Kingdom, as well as through partnerships in all parts of the world, we manage to be always close to our customers. The "Made in Germany" quality promise is more than just an empty phrase: with global sales, production takes place exclusively at the Jena site. Short distances and fast communication are clear advantages that set us apart from our competitors.

We invest a quarter of our annual turnover in research and development. The strategy is geared towards the long term. That, the establishment of new business units and teams, and the development of new products and technologies have meant growth over 30 years. In the beginning, the handful of employees were still housed in rented offices.

Today, the headquarters at Göschwitzer Straße 58/60 consists of a total of four buildings that bear witness to different eras of the company through their architecture. After all, growth also means change. The same applies to the company's management. Of the three long-standing managing directors, two have already been replaced by their own offspring. A change of generations in the medium-sized company, as it is written in the book. The helm is being handed over to the "young guns", but not in a hurry and without a plan, but bit by bit, with deep trust and healthy optimism.

And so we believe that history will continue, with similar success as in the past. The forecasts are good: electronics will keep mankind busy for a while yet. Our employees and colleagues have enough ideas for technologies that could fill even more company buildings. Our long-standing, loyal customers and partners place their trust in us anew every day. All with the aim of never losing the joy of technology.

GÖPEL electronic – Enjoy Testing!

Contact

Contact